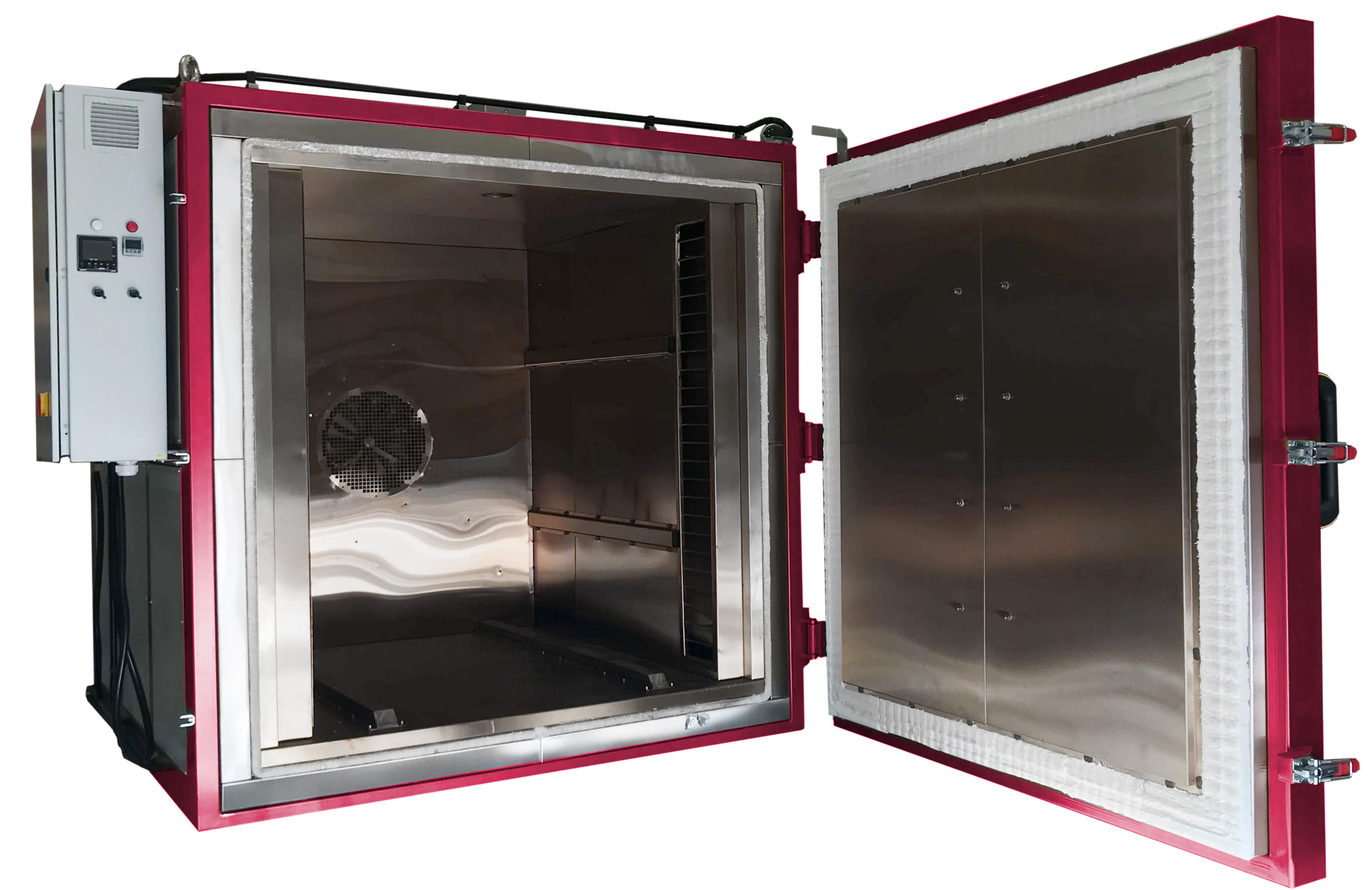

Floor standing industrial chamber furnaces with forced air circulation ICO

Professional chamber ovens ICO are made for tempering, annealing, ageing, preheating, drying, age hardening and other thermal treatment processes of various materials in temperature range from 50⁰C to 860⁰C in air conditions or with inertial gas (optional). Ovens goes with vertical or horizontal air circulation.

BASIC MODEL

• Strong and reliable frame construction

• Powder painted casing

• Chamber material:

< 260⁰C models: mild steel painted with heat resistant paints (Zinc coated mild steel or stainless steel optional)

< 360⁰C models: mild steel painted with heat resistant paints (stainless steel optional)

< 460-660⁰C models: stainless steel

< 860⁰C models: heat resistant stainless steel + insulation and bricks

• Heating elements mounted in double walls

• Forced air circulation

• Door opens to the side

• Door sealing with silicon gasket (260⁰C models)

• Door sealing with fiber tape (360⁰C-760⁰C models)

• Lightweight insulation (low inertia)

• Temperature uniformity <±5°C

• Solid state relay control

• PID temperature controller

• Thermocouple

• Independent over heat protection

• Ventilation (manually operated)

OPTIONS

• Chamber made from bricks

• Door made from bricks

• Silicon carbide bottom plates

• Silicon carbide protection of heating elements

• Heat resistant stainless steel bottom plate

• Cooling fan

• Container for inertial gas

• Container for cementation

• Inertial gas connection

• with flow meter

• Lifting up doors

• Automatic door opening(electromechanical, pneumatic, hydraulic)

• operated by foot or hand switch

• Ramp programmable PID controller

• Touch screen

• Temperature recorder

• Zone control

• Stationary table for load

• Turning table for load

• Sensors for emergency

• door stop

• Light signals

• Visual alarm for broken heating elements

• RS232